What is an air filter?

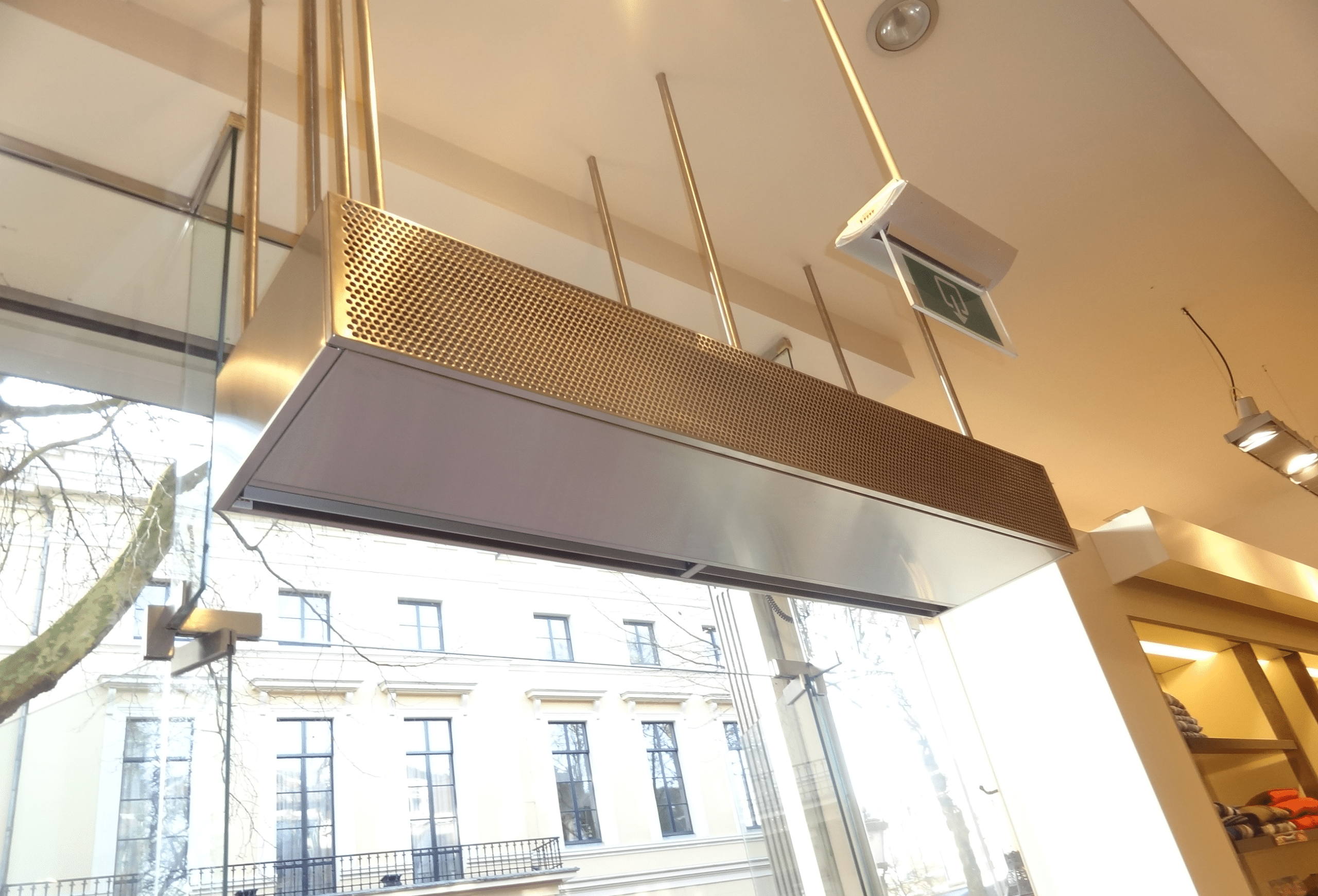

The Netherlands is highly urbanised, densely populated, and surrounded by numerous highways and railways, which negatively impacts outdoor air quality. Air filters remove harmful particles and gases from outdoor air. Additionally, they help extend the lifespan of ventilation systems and prevent unnecessary energy losses caused by contamination of heat exchangers and fans. As such, air filters are essential for maintaining healthy indoor air.

For example, air filters provide protection against particulate matter. People in the Netherlands are becoming increasingly aware of the importance of clean air. Respiratory infections and other lung diseases are receiving more media attention, emphasising the importance of choosing the right air filter. Everyone prefers to work in a safe environment, and clean air is a key part of that.

What types of air filters are there?

There are three different types of air filters:

-

Dust filters

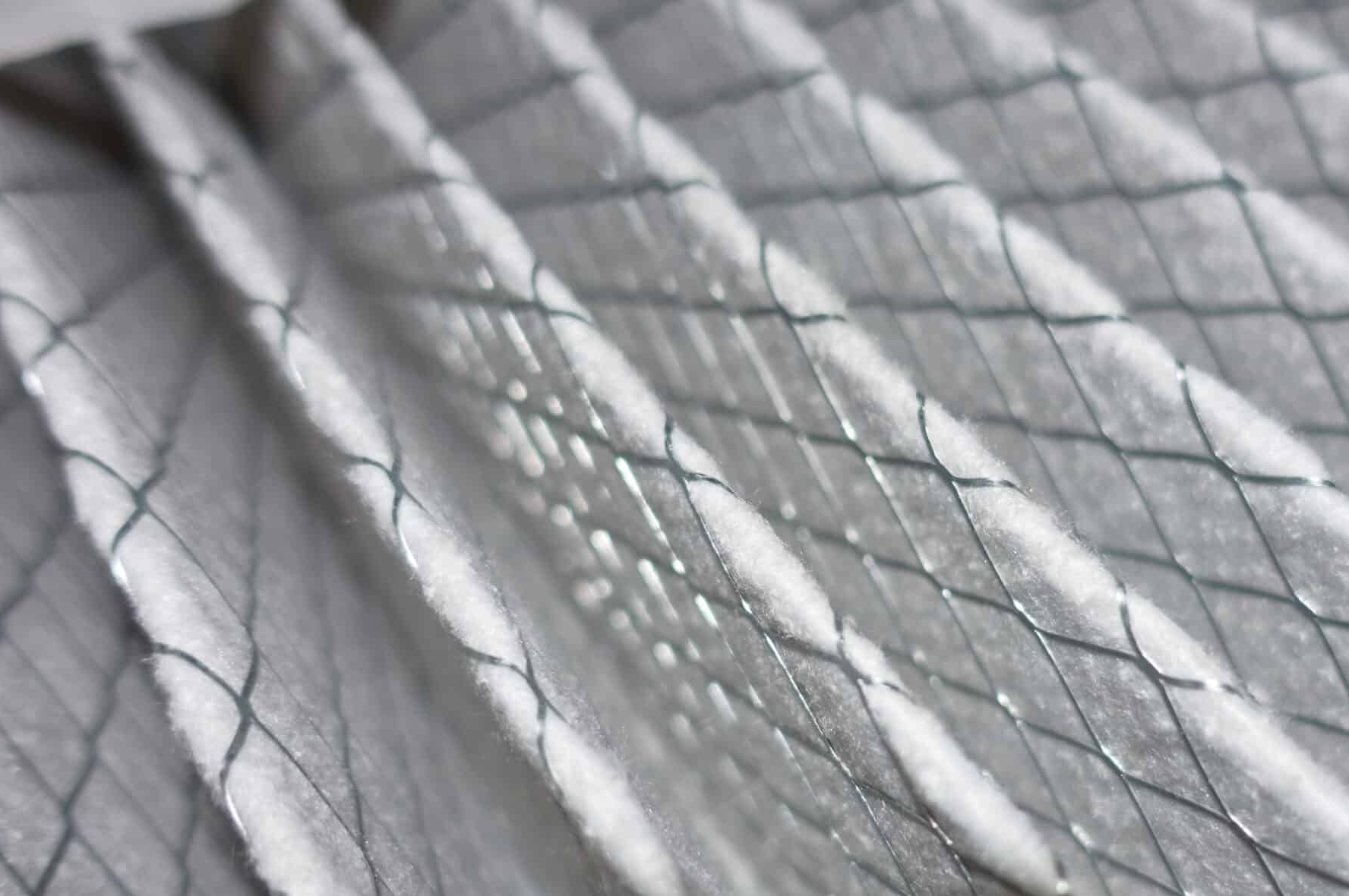

Dust filters capture particles as small as 0.3 microns (one-thousandth of a millimetre). These filters are available in coarse or fine versions. Examples include panel filters, compact filters, and bag filters.

-

(H)EPA filters

A common filter type is the (H)EPA filter, which stands for (High) Efficiency Particulate Air filters. Also referred to as Absolute filters, these are designed to capture airborne particles down to 0.3 microns. (H)EPA filters are frequently used in operating theatres and clean rooms.

-

Molecular filters

Molecular filters remove gaseous pollutants from the air. These include harmful substances such as NOx (nitrogen oxides) and NH3 (ammonia), as well as odours from cooking and sewage.

Standards

Air filters are tested according to international standards and are compared based on their properties. Most filters are tested under the global ISO 16890 standard, which replaced the European EN779:2015 standard in 2017. Based on their efficiency, fine dust filters are classified into specific categories according to the ISO 16890 standard.

Filter classes

Filter classes are divided into four main groups: ISO ePM1, ISO ePM2.5, ISO ePM10, and ISO Coarse. Within each group, filters are further classified based on the percentage of particles they capture. To qualify for a group, a filter must capture at least 50% of the specified particles.

The ISO 16890 standard has made it easier to identify which filter class is most suitable for specific conditions. The terms PM10, PM2.5, and PM1 correspond to particulate matter values measured globally by governments. The World Health Organisation (WHO) also uses these designations.

Advisory guidelines

To determine the most suitable air filter, professionals are no longer entirely dependent on market experts. Standards such as NEN EN 16798-3 and the guideline provide recommendations on which air filters are best to install. give advice on which air filter is best to install.

Eurovent

Eurovent has issued advisory guidelines (REC 4/23-2018) that recommend the minimum filter classes required to create healthy indoor air in specific situations. These guidelines consider the level of outdoor air pollution at the site as well as the use and occupancy of the building. Threshold values are based on the strict air quality guidelines established by the WHO.

RIVM

The RIVM has developed a system to indicate how air quality at specific times of the day affects health. This information allows individuals to minimise exposure to air pollution. Curious about air pollution in a specific area? Consult the Air quality index.

-

Healthy air guidelines based on WHO advisory standards:

Outdoor air quality Supply air classification PM values (μg/m3) SUP1 (highest)

PM2.5 ≤2.5

PM10 ≤5SUP2

PM2.5 ≤5

PM10 ≤10SUP3

PM2.5 ≤7.5

PM10 ≤20SUP4

PM2.5 ≤10

PM10 ≤20SUP5 (lowest)

PM2.5 ≤15

PM10 ≤30Minimum recommended filter class (ISO 16890) ISO ePM1 ISO ePM1 ISO ePM2.5 ISO ePM10 ISO ePM10 ODA 1 70% 50% 50% 50% 50% ODA 2 80% 70% 70% 80% 50% ODA 3 90% 80% 80% 90% 80% -

Outdoor air (ODA)

ODA 1: (PM2.5 ≤ 10 μg/m3 and PM10 ≤ 20 μg/m3)

refers to outside air that is only temporarily polluted.ODA 2: (PM2.5 ≤ 15 μg/m3 and PM10 ≤ 30 μg/m3)

refers to outdoor air with high concentrations of particulate matter.ODA 3: (PM2.5 >15 μg/m3 and PM10> 30 μg/m3)

refers to outdoor air with very high concentrations of particulate matter. -

Supply air (SUP):

Class Description Examples SUP 1

(PM2.5≤10μg/m3 & PM10≤5μg/m3)

Industrial toapplications with demand for high hygienic requirements: - Hospitals

- Pharmaceutical industry

- Electronics

SUP 2

(PM2.5≤5μg/m3 & PM10≤10μg/m3)Rooms with permanent occupancy: - Childcare

- Schools

- Offices

- Hotels

- Housing

- Conference rooms

- Meeting rooms

- Exhibition halls

- Cinemas

SUP 3

(PM2.5≤7.5μg/m3 & PM10≤15μg/m3)

Rooms with temporary occupancy: - Sheds

- Shopping centres

- Washrooms

- Copy rooms

- Server rooms

SUP 4

(PM2.5≤10μg/m3 & PM10≤20μg/m3)Rooms with short occupancy: - Toilets

- Storage rooms

- Staircases

SUP 5

(PM2.5≤15μg/m3 & PM10≤30μg/m3)

Unoccupied rooms: - Manufacturing areas with heavy industry such as steel mills,

smelters and foundries.

New class designation

Unfortunately, it is not possible to directly convert old class designations (EN779:2012) into new ones (ISO 16890). This is due to significant differences in testing methods. Test results depend on factors such as the type of filter and the filter material. Consult an air filter specialist to determine the filter class of your air filters.

Maintenance

Systems, including air filters, should be designed and installed to facilitate monthly inspections and maintenance. To ensure optimal performance, these inspections should be carried out by a qualified professional.

-

When should air filters be replaced?

- In case of visual leaks and damage

- When the air filter is soaked

- After construction or renovation work

- Upon reaching the specified end resistance (as indicated by the AHU manufacturer or system supplier)

- Ideally after the pollen season in autumn and/or after the heating season in spring

-

When changing air filters, pay attention to the following points:

- Store spare filters dry and clean in their original packaging

- During air filter changes, wear protective clothing, such as a face mask and gloves

- Carefully pack used air filters to prevent the release of contaminants.

- Install new air filters according to the manufacturer’s instructions to avoid damage, such as bent pockets

- Check the zero value of the differential pressure gauge and the operating hours counter

- Record the filter change date, resistance of the new filters, next replacement date, and the name of the person performing the replacement on a service card

- Dispose of used air filters (both outdoor and recirculation filters) as industrial waste.

Filters that have collected harmful substances must be disposed of as chemical waste. Always comply with environmental regulations when doing so.